Nitronic® 30

Nitronic® 30 - HPA N30 - UNS S20400 - N30 Steel - N & Mn Strengthened Stainless Steel

Home > All Alloys > HPA N30

| Table of Contents | |

|---|---|

| Datasheet | Chemistry |

| Inventory | Applications |

| General Data | Mechanical Properties |

| pecifications | Physical Properties & Application Data |

| Machining, Welding, & Processing | References |

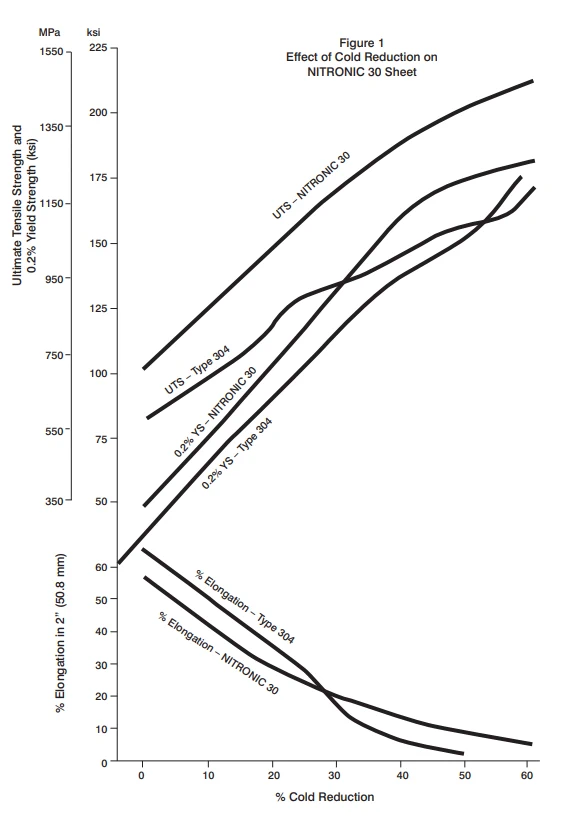

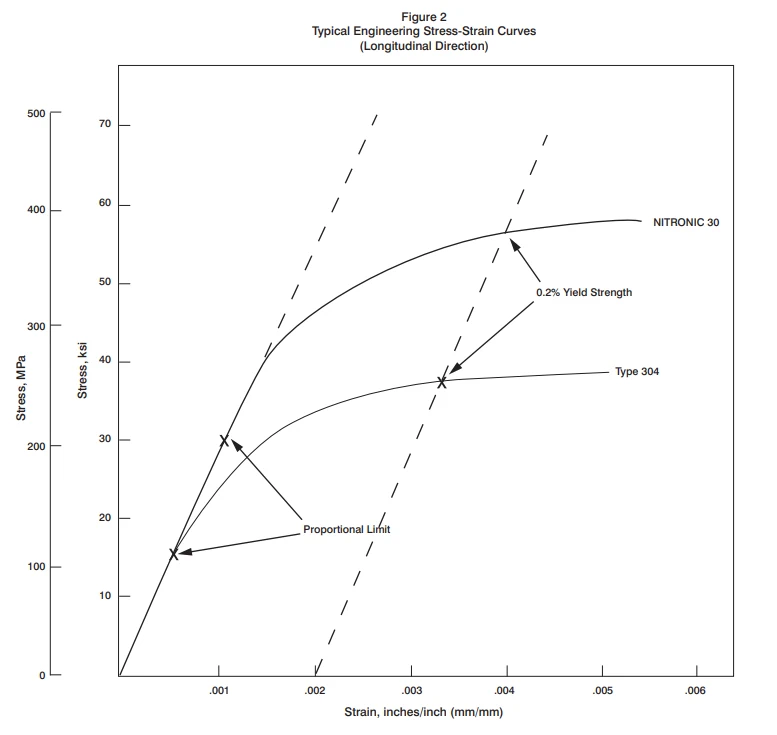

N30 is a Nitrogen and Manganese strengthened stainless steel developed for applications requiring a good level of aqueous corrosion resistance combined with good toughness and economy. N30 stainless steel provides approximately 50% higher yield strength than Type 304L and, therefore, may allow lighter gauges to further reduce costs. N30 stainless steel work hardens rapidly while retaining good ductility. Unlike other nitrogen-strengthened stainless steels, N30 stainless steel is subject to magnetic transformation when cold worked.

Datasheet

View or download Cleveland Cliffs' Nitronic 30 datasheet here

Chemistry*

| Min% | Max% | |

|---|---|---|

| Fe | Bal. | |

| Cr | 15.0 | 17.0 |

| Ni | 1.50 | 3.0 |

| Mn | 7.0 | 9.0 |

| N | 0.15 | 0.30 |

| Si | 1.00 | |

| C | 0.03 | |

| Cu | 1.00 | |

| P | 0.040 | |

| S | 0.030 |

Typical Inventory

We've expanded our in-house capabilities in:

- wire drawing conversions,

- hex bar coversions,

- draw bench cold work,

- and cold finish machining capability range of +/- 0.00025" Ø.

For more information, you can contact us at 1-800-472-5569, and request our sales department. You can also view our brochure online! There's also more information about our offered services on our production services page.

Applications

N30 Stainless Steel offers significantly higher strength than Type 304 and potential for applications requiring good resistance to aqueous and atmospheric corrosion resistance combined with good toughness and economy.

Specific potential applications include automotive hose clamps, safety belt anchors, truck and bus frames, water supply and control structures, sewage treatment plant structures, bulk solids handling equipment, magnetic ore separator screens, coal buckets, and hopper cars.

Stainless steels have served successfully in many structural components in the transportation industry. Bus space frames and bumpers take advantage of the excellent fabricability, high strength, and toughness of this stainless steel. Tensilized N30 stainless steel has been used in rapid transit structures where the strength-to-weight ratio of up to three times that of carbon steel has improved operating efficiency. Rear frames of refrigerated trucks are easily welded and formed from N30 stainless steel resulting in protective units that can withstand impact blows without cracking. Shipboard container structures use this stainless steel successfully over carbon steel due to scuffing that inevitably rusts wherever the protective paint is damaged.

General Data

- Excellent mechanical properties at both extremely low and extremely high temperatures.

- Outstanding resistance to pitting, crevice corrosion, and intercrystalline corrosion.

- Almost complete freedom from chloride induced stress corrosion cracking.

- High resistance to oxidation at elevated temperatures up to 1050 °C.

- Good resistance to acids such as nitric, phosphoric, sulfuric, and hydrochloric, as well as to alkalis makes possible the construction of thin structural parts of high heat transfer.

Common Specifications

Note that the specifications listed are common for this alloy but are for reference only and may be specific to a certain form. The specifications listed are not comprehensive nor indicative of any edition, revision, or similar such as an amendment. Please, reach out to our sales department to request the Material Test Report (MTR) or to confirm your required specifications.

| Form | Standard |

|---|---|

| Identification | UNS S20400 |

| Sheet & Plate | ASTM A240, ASTM A666, ASME SA240 |

| Weld Wire | N50W/ UNS S20980/ AWS A5.9 Class ER209 |

Mechanical Properties

The typical properties listed can usually be provided in rounds, sheet, strip, plate, & custom forgings. We have the equipment to produce small quantities in special sizes to meet our customers’ specific needs. The table below shows Cleveland Cliffs' Typical Room Temperature Mechanical Properties of Nitronic® 30 Stainless Steel. For most common forms and exceptions, check out the datasheet linked underneath the table.

| UTS ksi (MPa) | 0.2% YS ksi (MPa) | Elong. in 2 in., % | Rockwell Hardness |

|---|---|---|---|

| 110 (758) | 55 (379) | 50 | 95B |

UTS = Ultimate Tensile Strength, YS = Yield Strength

Link to Cleveland Cliffs' datasheet on Nitronic® 30Effect of Cold Work on Ferrite Number

Unlike the other Nitronic alloys, N30 will undergo magnetic transformation due to cold reduction. This magnetism is the result of forming deformation martensite with cold work. This martensite increases the strength, work hardening rate, and abrasion resistance of the alloy.

| % Cold Work | Ferrite Number* |

|---|---|

| 0 | 0 |

| 10 | 3 |

| 20 | 10 |

| 30 | 21 |

| 40 | 27 |

*As determined from a Ferritescope by Fisher Technology. The Ferritescope measures the % magnetic phase. Ferrite Number is therefore proportional to the amount of martensite present.

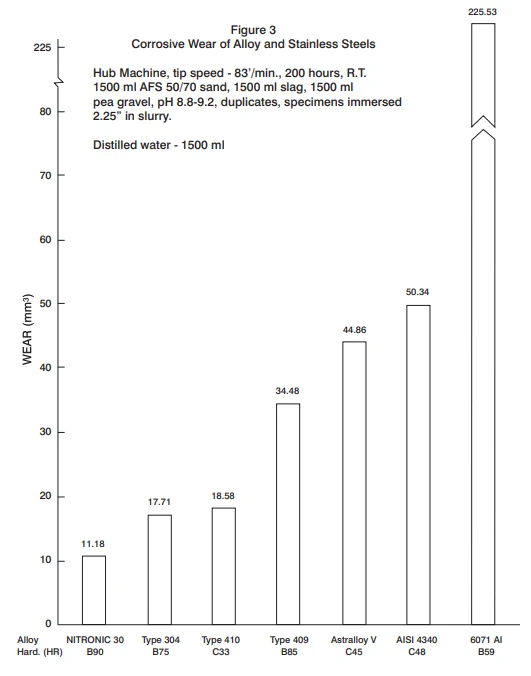

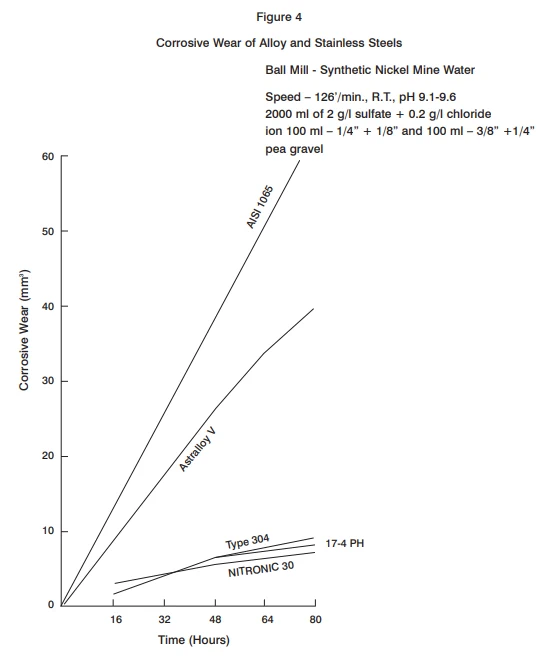

Wear Resistance

N30 has outstanding corrosive wear resistance under many different siding codintions. The stainless steels as a class are much more abrasion resistant than abrasion resistant (AR) steels under even mildly corrosive conditions. N30 is more cost effective than Types 409 and 304, which are typically used in wet abrasive applications.

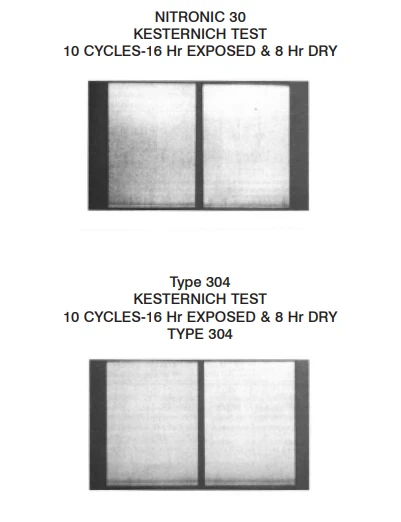

Corrosion Resistance

N30 stainless steel exhibits good corrosion resistance to a variety of media. Pitting resistance, as measured by tests in 10% FeCl3 solution, is better than Type 304. In sulfuric acid and hydrochloric acid, N30 is much better than Types 409 and 410 and approaches Type 304 in more dilute solutions. Atmospheric corrosion resistance is shown in Figure 5.

Weldability

Early experience with stainless shows good welding characteristics. It can be fusion welded with the usual arc welding processes employed for austenitic stainless steels. N30 provides superior ductility and toughness, as well as resistance to weld cracking without the need for preheating or postheating, as most martensitic and heavy gauge ferritic stainless steels require. A small quantity of ferrite will form in autogenous N30 stainless welds to minimize any hot cracking sensitivity. Arc welding parameters more closely approximate those of the other NITRONIC grades (e.g., slower weld travel, hotter shielding gas for GTAW - Ar + 5% H2 or He), rather than the standard austenitic stainless steels. Standard AWS austenitic stainless fillers or the newly included AWS A5.9 and A5.4 Nitronic fillers (209, 240, 218, 219) can be selected for any particular application.

References

Link to Cleveland Cliffs' datasheet on Nitronic® 30Nitronic® is a registered trademark of Cleveland-Cliffs Steel Corp, successor to AK Steel.

Data referring to mechanical properties and chemical analyses are the result of tests performed on specimens obtained from specific locations of the products in accordance with prescribed sampling procedures; any warranty thereof is limited to the values obtained at such locations and by such procedures. There is no warranty with respect to values of the materials at other locations.