Unleashing Excellence: The Radial Forge GFM® Advantage

At the forefront of forging technology, the radial forge GFM® stands as a beacon of precision and innovation. Specializing in the cold work of alloys N60 and N50, HPA is redefining industry standards, offering expertise and advanced mechanical solutions to meet the ever-evolving demands of modern engineering.

Level 6 is noted by its minimum ultimate tensile strength of 230 Ksi. By cold working our materials, we retain better elongation values through grain structure improvements that reduce the brittleness often associated with high strength materials. While our level 6 is primarily offered for alloys N50 and N60, we also cold work alloy C276, and are willing to try research for your high-performing alloy requirements.

For more information, check out our popular high strength options N60 HS and N50 HS.

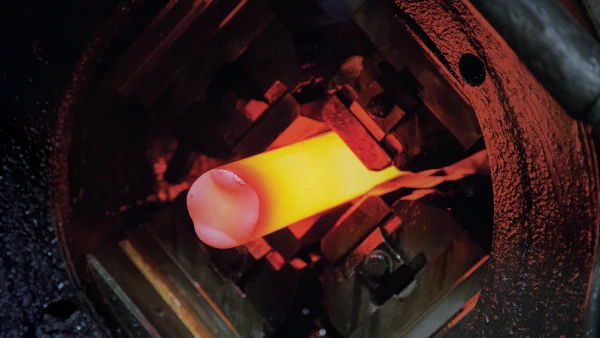

About Radial Forge GFM®

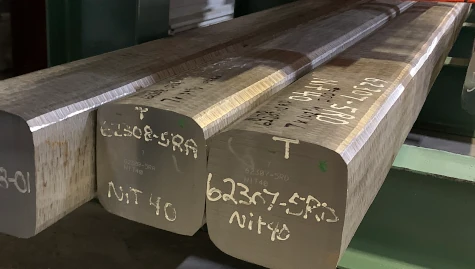

The radial forging GFM®, also known as rotary forging or rotary swaging, is a pioneering piece of equipment in the field of precision forging, and HPA is leveraging cutting-edge technology and decades of experience to deliver top-notch alloy services. Our commitment to excellence is reflected in every aspect of our operations, from the meticulous planning to the seamless execution of forging processes. The GFM® is a radial forge that uses a series of hammers that forge the material in rotation. While this rotary forge technique can be done hot or cold, HPA has been perfecting the cold process for decades. Ideal for applications requiring robust materials with elevated mechanicals, alloys undergo specialized cold working processes at our radial forge GFM®, enhancing their mechanical properties and tested to ensure they meet the highest quality standards. This special processing puts the hardness in the center of the material, and when further cold drawn can help to provide a more thorough hardness profile.

Cold Work Alloys N60 and N50: The Epitome of Strength and Durability

Our focus on cold working alloys N60 HS and N50 HS sets us apart in the competitive landscape. These alloys are renowned for their exceptional strength, durability, and resistance to corrosion and wear as well as at elevated temperatures. Cold working these alloys helps to provide exceptional performance in mission critical applications. Especially, alloy N60 that is renowned for its non-seizing characteristics making it a top choice in extreme environments with metal on metal contact whether that is a actuator, bushing, valve, or fastener.

We've expanded our in-house capabilities in:

- wire drawing conversions,

- hex bar coversions,

- draw bench cold work,

- and cold finish machining capability range of +/- 0.00025" Ø.

For more information, you can contact us at 1-800-472-5569, and request our sales department. You can also view our brochure online! There's also more information about our offered services on our production services page.